- Browse Categories

- Cellulose Ether

- HPMC

- HEC

- CMC

- RDP

- Starch ether

- PAC

- Certifications

-

- Subscribe

-

Get email updates on new products

- Contact Us

- We are specialized in cellulose ether production such as Hydroxypropyl methyl cellulose (HPMC), Hydroxyethyl cellulose (HEC), Sodium carboxymethylcellulose (CMC), Redispersible polymer powder (RDP) and Polyanionic cellulose (PAC) etc, more than 10 years' experiences in this field, with ISO, SGS, AHF, FDA certification and extreme standard let us keep very competitive in the current market. Contact Now

Surface Treatment HPMC Powder Used For Water Based Paint

- Item : Hydroxypropyl methyl cellulose

- Appearance : White powder

- Methoxy (%) : 25-30

- Hydroxypropoxy (%) : 9-12

- Partical Size (μm) : ≤155

- Drying Loss Ratio (%) : ≤5.0

- Viscosity (mPa•s) : 60000-80000

- pH Value : 5-9

- Water Retention Ratio (%) : ≥90

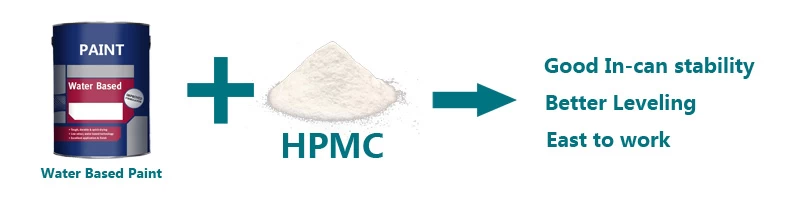

Water-based paint is a viscous liquid produced with resin, or oil, or emulsion, with corresponding additives, and formulated with organic solvents or water. Water-based paints with excellent performance should also have excellent handling properties, good hiding power, strong coating film adhesion, and good water retention properties; WelCel hpmc cellulose is the most suitable raw material for these properties.

1 The water retention performance of cellulose hpmc powder provides excellent coating performance for latex coatings, especially high PVC coatings. When the coatings are thick paste, highly reduce flocculation increase thickening effect,

2It can reduce the dosage and improve the economy of the formula

3 Improve the suspension of the coating system. When it is in a static state, maintain the best thickening state of the coating; when it is poured, it has excellent fluidity and will not splash;

4 It is easy to spread on the substrate and convenient for construction during brushing and roller coating;

5 when the coating is finished, the viscosity of the system will recover immediately, and the coating will sag immediately.

The WelCel hpmc with proper surface treatment can effectively prevent agglomeration during dissolution and fully disperse. Sufficient dissolution time and viscosity rise speed can simplify the production process; the modified Max cellulose ether also has good mildew resistance , Provide sufficient coating storage time, effectively prevent pigment and filler sedimentation.

.jpg.webp)