- Browse Categories

- Cellulose Ether

- HPMC

- HEC

- CMC

- RDP

- Starch ether

- PAC

- Certifications

-

- Subscribe

-

Get email updates on new products

- Contact Us

- We are specialized in cellulose ether production such as Hydroxypropyl methyl cellulose (HPMC), Hydroxyethyl cellulose (HEC), Sodium carboxymethylcellulose (CMC), Redispersible polymer powder (RDP) and Polyanionic cellulose (PAC) etc, more than 10 years' experiences in this field, with ISO, SGS, AHF, FDA certification and extreme standard let us keep very competitive in the current market. Contact Now

Construction Grade HPMC

- Item : Hydroxypropyl methyl cellulose

- Appearance : White powder

- Methoxy (%) : 25-30

- Hydroxypropoxy (%) : 9-12

- Partical Size (μm) : ≤155

- Drying Loss Ratio (%) : ≤5.0

- Viscosity (mPa•s) : 150000-200000

- pH Value : 5-9

- Water Retention Ratio (%) : ≥90

Product description

China cellulose adhesive (supplier) is a very important component in building materials that provides better water retention, strength and adhesion to cement, lime and gypsum based products.

Cellulose ethers make it impossible to industrialize high quality mortars.

China hpmc cellulose chemical (factory) is one of the most important cellulose ether used in construction chemical, it can be used as wall tile, floor tile adhesive, ceramic tile glue, construction mortar, self leveling, putty powder, it can offer better water retention, anti-sagging, good workability, wet ability, longer open time.

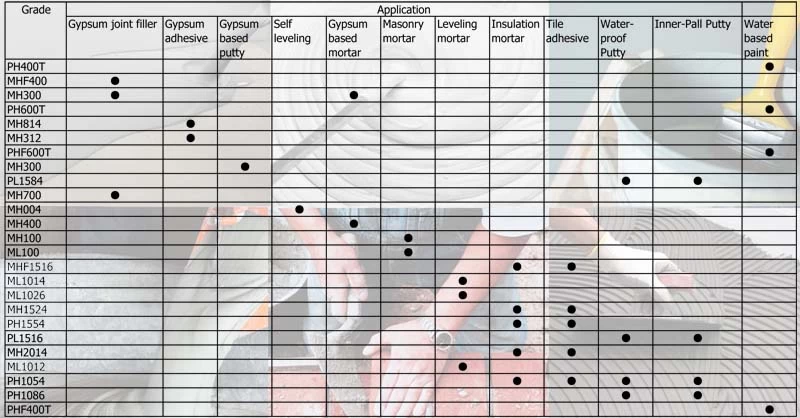

We offer different viscosity hpmc for construction used in different application.

Application

Constriction chemical HPMC is mainly used in Putty powder, gypsum, tile adhesive, self leveling, cement mortar etc.

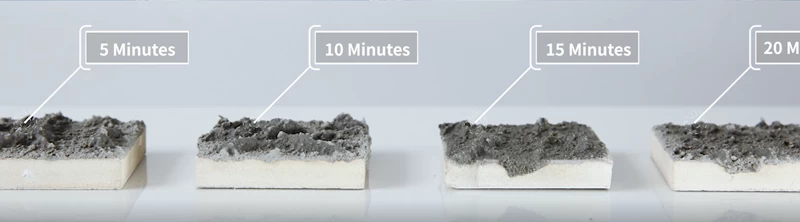

HPMC for Putty powder

Putty is a thin layer of leveling or modelling plastering material that is widely used in the world. It has been used for more than 30 years and is very important for the decorative function of the walls, as three layers of coating: the wall, the putty layer and the paint layer. Due to the difference in deformation coefficient, when the ambient temperature changes, the deformation of the three layers will be different, which inevitably leads to stress concentrations that need to be relieved by the elasticity of the putty layer. A good putty will make the wall smooth and seamless. In addition to providing a smooth or textured base for latex paint, by optimizing the formula, the putty can also reduce the amount of latex paint used and extend the life of the paint.

Powder coating production and application are very convenient, just add water and mix evenly can be used, in its formulation, cellulose for the powder coating provides good suspension effect, efficient wetting capacity of the base surface, brushability, efficient water retention capacity.

Welldone™ HPMC offers the following advantages to wall

1. Excellent water retention for longer application time and improved work efficiency.

2. High lubricity, making the construction easier and smoother. It provides a fine and even texture, making the surface of the putty smoother.

3. High viscosity for better adhesion of the putty to the wall.

4. Improve shrinkage and crack resistance, improve surface quality.

Hpmc for gypsum

Gypsum-based wall is a functional ecological wall. The use of gypsum as a cementitious material makes the hollowing and cracking problems of traditional cement-based materials disappear forever, especially after the adoption of mechanical construction, which not only improves efficiency, but also ensures the quality of the project.

Gypsum is a kind of building material that will form a large number of micropores in the material after curing, and its porosity makes the wall has a breathing function and sound absorption and sound insulation effect, this breathing function can regulate the humidity of the living and working environment and create a comfortable microclimate, making gypsum play an increasingly important role in modern interior decoration.

HPMC is essential in gypsum-based products, whether in gypsum-based leveling mortars, caulking compound, putty or gypsum-based self-leveling; it has certain set-retarding effects on gypsum-based products.

Welldone™ HPMC is not sensitive to the alkalinity of gypsum, it can be quickly infiltrated in all kinds of gypsum products without agglomeration, and has no negative influence on the porosity of cured gypsum products, so as to ensure the breathing performance of gypsum products; with appropriate wet adhesion to ensure the bonding ability of the material to the substrate, which greatly improves the construction performance of gypsum products, and is easy to spread without sticking to tools.

Welldone™ HPMC offers the following advantages to gypsum plaster:

1. Improve the uniformity, make the plaster easier to coat,

2. Improve the anti-sagging ability to enhance the fluidity and pump ability and improve work efficiency.

3. High water retention, extend the working time of the mortar, and produce high mechanical strength during solidification.

4. By controlling the consistency of the mortar, a high-quality surface coating is formed.

Hpmc for tile adhesive

Tile is a widely a kind of functional decoration material that is widely accepted and loved by everyone which has been widely used around the world. Welldone™ HPMC can ensure the smooth construction of different types of tiles on different base surfaces, like wall tile adhesive, floor tile adhesive etc, even in the case of harsh ambient temperature; it can give the tile adhesive a long enough open time and adjustable time. For the tile adhesive, it should be easy to mix, easy to operate, non-stick knife; also have good anti-hanging effect; good initial adhesion. When the pasting method is changed to the trowel method, the requirements for the tile binder are: easy to mix, easy to spread, non-stick trowel; good anti-sagging ; long open time, good wetting; long adjustable time. Welldone™ HPMC provide tile adhesive with excellent water retention, workability, and sag resistance. Especially, Welldone™ HPMC helps to increase adhesion strength and open time.

Welldone™ HPMC offers the following advantages to tile glue:

1. Greatly improve the water retention capacity, inhibit the high water absorption tiles and substrates from losing a lot of water, so that the cement has enough water to harden state, improve the bond strength, and further improve the mortar's slip resistance;

2. Good open time and adjustable time, easy for workers to adjust the error of placing the wrong ceramic;

3. Makes dry-mix ingredients easy to mix without creating clumps, which saves working time. It also makes construction faster and more efficient, improves workability, and reduces costs.

4. Mortar has better plasticity and flexibility, making construction easier and work more efficient;

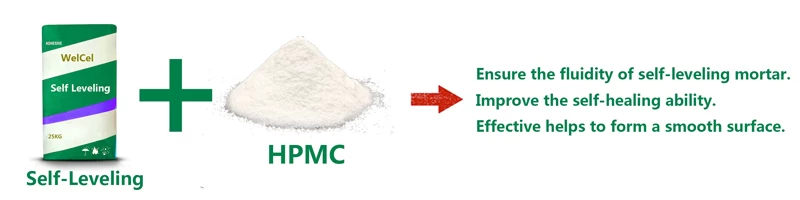

Hpmc for self leveling

Self-levelling mortar is a special dry-mix mortar product with self-leveling and self-compacting function, and its self-leveling and self-compacting ability is essential for achieving a smooth and seamless ground layer. A good self-leveling mortar should have suitable operation performance as a first choice, that is, to maintain its leveling and self-healing ability in the construction time, which requires the mortar to ensure its uniformity and stability in this time period. Secondly, it should also have certain strength, including bearing capacity and the binding force to the substrate, which is the basis for the normal application of flooring materials. Cellulose products play a vital role in the realization of these properties. Cellulose can effectively suspend the coarse aggregate in the mortar to ensure the flow of the mortar and the operability of the time; reduce the mortar contraction; reduce water secretion, improve the surface effect of the mortar after construction and improve its wear resistance.

Welldone™ HPMC offers the following advantages to self leveling :

1. Ensuring the flow of self-leveling mortar.

2. Improving the self-healing ability of self-leveling mortars.

3. Contributes to the formation of a smooth surface.

4. Reduced shrinkage and increased load-bearing capacity.

5. Improve the adhesion and cohesion of self-leveling mortar to the substrate.

Cement mortar is an important and indispensable component of the construction industry. Welldone™ HPMC can improve the construction performance, spraying and pumping properties of mortar; their thickening ability can improve the wetting ability of wet mortar to the substrate, improve the bond strength of mortar, adjustable time and resistance to dry shrinkage; make the cement hydration more complete and thus improve the structural strength.

Welldone™ HPMC offers the following advantages to cement mortar :

1. Increase water retention,

2. extend operating time,

3. Improve efficiency, and effectively prevents loss of strength and cracking caused by excessive drying and insufficient hydration.

4. Strong bonding ability, good sag resistance very good thickening effect, adding in dry mortar can increase the viscosity of thousands of times.

.jpg.webp)